Contact Us

INTCO’s Medical Wheelchair From Prototype to Mass Production Process

The process of developing an advanced INTCO medical wheelchair starts with thorough planning and assessment. The initial phase of research and development includes extensive market analysis and studies of user requirements. These investigations help the company understand both market trends and the specific needs of users. During this phase, data is collected from a variety of sources such as surveys, industry reports, and academic studies. This information forms the basis for conceptualizing the medical wheelchair designs.

Initial Research and Development Phase

In the first stage, researchers at INTCO focus on identifying gaps in existing medical wheelchair offerings. They delve into the functional, ergonomic, and aesthetic aspects, ensuring a comprehensive understanding. This multi-dimensional approach allows the team to pinpoint what would make their product stand out. During this phase, potential obstacles are also assessed, helping to predict challenges that could arise later in the development process. This thorough groundwork ensures that the progression to the next stages is smooth and well-informed.

Incorporating Feedback into Research

INTCO employs a multi-feedback loop mechanism, where firsthand user feedback is constantly solicited and integrated. Prototype models are tested by a diverse group of users who provide critical insights on comfort, maneuverability, and overall usability. This iterative process ensures that every aspect of the wheelchair is fine-tuned. The goal is to create a product that not only meets regulatory requirements but also provides an enhanced user experience. This meticulous attention to detail during the prototyping stage culminates in an optimized medical wheelchair that embodies durability, comfort, and functionality.

As one of the famous brands in the production and manufacture of medical wheelchairs and mobility scooters, it is a high-tech manufacturing company committing to R&D, production and marketing of medical consumables and durable medical equipment with main business covering medical consumables, rehabilitation equipment, physiotherapy care, etc.

Up to now, with a good product reputation, INTCO Medical has been exported products to more than 120 countries and regions in America, Europe, Asia, Africa and Oceania, which is providing practical products and high-quality services to over 10,000 clients.

Prototyping the Medical Wheelchair

Selection of Materials and Components

Creating a prototype for the INTCO medical wheelchair necessitates a meticulous choice of materials and components. The goal is to find an optimal balance between durability, weight, and cost. Typically, high-grade aluminum and steel are chosen for the frame to provide strength. When selecting components such as wheels, cushions, and armrests, factors like wear resistance and comfort are prioritized. Advanced materials, including memory foam and high-tensile plastics, are frequently used to improve user experience and extend the product’s lifespan.

Advanced Design Techniques Employed

Advanced design techniques play a pivotal role in the manufacture of wheelchairs, ensuring that each model is both functional and user-friendly. The integration of ergonomic principles guarantees comfort, while materials science advancements, such as carbon fiber and lightweight alloys, enhance durability and maneuverability. Additionally, automated assembly lines and intelligent packaging robots streamline production, resulting in high-quality, consistent outputs. This blend of cutting-edge technology and meticulous design ensures that INTCO Medical’s wheelchairs meet the highest standards of safety, comfort, and reliability.

Testing and Evaluation Procedures

Finally, the prototypes undergo rigorous testing and evaluation procedures. INTCO adheres to both internal standards and international regulatory requirements to ensure the medical wheelchair’s safety and reliability. Mechanical tests assess the durability under various conditions, including weight-bearing and impact resistance. User trials are also an integral part of this phase, where individuals test the wheelchair in different environments and provide feedback on performance, ease of use, and comfort. These comprehensive evaluations are crucial in refining the product before it moves to mass production.

Through a seamless integration of research, expert collaboration, meticulous prototyping, and rigorous testing, it effectively transforms innovative wheelchair concepts into high-quality, reliable products designed to improve mobility and quality of life. The resulting medical wheelchair is a testament to the company’s commitment to excellence and its dedication to meeting the needs of its users.

From Prototype to Mass Production

Streamlining Manufacturing Processes

Implementing Lean Production Methods

The process of moving from prototype to mass production at INTCO requires careful application of lean production techniques. Lean production emphasizes the reduction of waste and the enhancement of efficiency, which is especially important when expanding operations. By implementing these techniques, INTCO guarantees that the manufacturing procedure remains both cost-effective and time-efficient, all while maintaining the high quality of the medical wheelchair. The incorporation of continuous improvements and feedback loops is essential to lean production, allowing the company to swiftly adjust to any unexpected challenges encountered during scaling.

Automation Integration for Efficiency

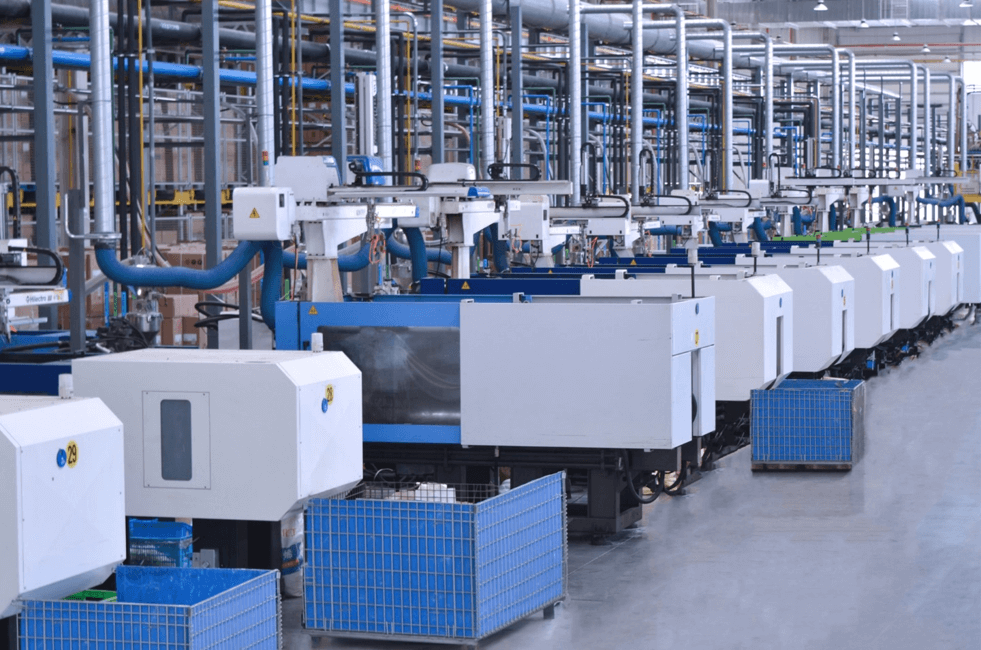

In the mass production stage, INTCO integrates automation to enhance manufacturing efficiency. Automation minimizes human error and allows for consistent product quality. Robotic arms and automated assembly lines can handle repetitive tasks with precision, ensuring that each medical wheelchair meets the stringent quality standards set during the prototyping phase. Additionally, automation can significantly reduce production time, allowing the company to meet higher demand without sacrificing the reliability and performance of the wheelchairs.

Quality Assurance Measures in Production

Ensuring that each medical wheelchair meets the highest quality standards is a core principle at INTCO. During mass production, extensive quality assurance measures are implemented. These include both in-line and end-of-line inspections to detect any defects or inconsistencies. Advanced testing equipment and processes are employed to verify the durability, safety, and functional performance of the wheelchairs. Quality control teams conduct random sampling and stress tests, ensuring that every unit produced can withstand real-world conditions and meet user expectations.

Application and Distribution

Ensuring Compliance with Health Standards

Compliance with health standards is paramount for the credibility and safety of INTCO’s medical wheelchairs. The company strictly adheres to international standards and regulations governing medical devices, including ISO and FDA guidelines. Compliance ensures that the wheelchairs are safe for use in various healthcare environments, such as hospitals and rehabilitation centers. Detailed documentation and certification processes are maintained to validate that every wheelchair produced meets these stringent health standards, protecting end-users and enhancing institutional trust.

Effective Distribution Strategies

Once production reaches its peak, having effective distribution strategies is crucial to ensure that the medical wheelchairs are delivered to their intended users both promptly and efficiently. INTCO utilizes a multi-channel distribution approach. This includes forming partnerships with medical supply distributors, utilizing online platforms, and employing direct sales teams. Logistics management is vital in this process as it guarantees timely delivery while also optimizing shipping costs. Additionally, strategic warehousing and inventory management play significant roles in responding swiftly to market demands, ensuring that wheelchairs are readily available wherever and whenever they are needed.

Through meticulous planning, advanced manufacturing techniques, strict quality assurance, and strategic distribution, INTCO successfully transitions innovative wheelchair designs from prototype to mass-produced products. These efforts reflect the company’s unwavering commitment to enhancing mobility and quality of life for users around the globe.

The Future of INTCO’s Medical Wheelchairs

Continuous Improvement Initiatives

Continuous improvement is a cornerstone of INTCO’s commitment to delivering high-quality medical wheelchairs. The company engages in ongoing research and development efforts aimed at enhancing both product and process efficiency. By investing in cutting-edge technologies and integrating real-time analytics into the manufacturing process, it continuously refines its production methods. These improvements not only enhance product quality but also make the manufacturing process more sustainable and cost-effective.

Moreover, INTCO implements a robust system of performance metrics to monitor and evaluate the effectiveness of these initiatives. KPIs related to material usage, production times, and quality control are regularly assessed and optimized. This rigorous approach ensures that any issue is addressed promptly, and improvements are implemented swiftly, contributing to the overall reliability and innovation of the medical wheelchair product line.

Jiangsu Intco Medical Products Co., Ltd focuses on the research, production, and marketing of rehabilitation equipment and therapy products. We specialize in manual and electric wheelchairs, mobility scooters, transfer machines, walking aids, commode chairs, and canes. With hundreds of automated machines, we can produce 1,000,000 manual wheelchairs and 100,000 electric wheelchairs annually, serving over 66 countries and regions worldwide.

Expanding the Product Line and Market Reach

INTCO’s vision for the future extends beyond improving its current products. The company is also keen on broadening its product line and market reach. This strategy includes developing new models of medical wheelchairs designed to meet diverse user needs. For instance, they are working on lightweight and portable options for active users, as well as more robust, feature-rich models for individuals with advanced mobility requirements. By exploring new materials and technologies, the aim is to innovate and maintain a competitive edge in the medical device market.

The expansion strategy also includes penetrating new geographical markets and strengthening its presence in existing ones. By forming strategic partnerships with international distributors and participating in global healthcare exhibitions, it aims to introduce its medical wheelchairs to a broader audience. Additionally, leveraging digital platforms for marketing and sales enables the company to connect with customers directly, providing them with detailed product information and exceptional customer service.

INTCO’s emphasis on continuous improvement and strategic expansion reflects its commitment to enhancing mobility and quality of life for users around the globe. Through these initiatives, the company not only aims to meet the evolving needs of its customers but also to set new standards in the medical wheelchair industry.