Contact Us

How Wheelchair Suppliers Guarantee Top-Notch Product Quality

Importance of Wheelchair Suppliers

Wheelchair suppliers play a role in providing individuals facing mobility difficulties with products that are both effective and trustworthy in terms of comfort and safety needs for users’ independence to be maintained properly maintained. A top priority, for these wheelchair suppliers, is to maintain product quality as it significantly affects the overall experience and safety of users by ensuring top-tier performance and longevity through the use of cutting-edge manufacturing methods and thorough testing protocols.

Introduction of INTCO Medical

As one of the famous brands in the production and manufacture of medical wheelchairs and mobility scooters, INTCO Medical is a high-tech manufacturing company committing to R&D, production and marketing of medical consumables and durable medical equipment with main business covering medical consumables, rehabilitation equipment, physiotherapy care, etc.

Up to now, with a good product reputation, INTCO Medical has been exported products to more than 120 countries and regions in America, Europe, Asia, Africa, and Oceania, which is providing practical products and high-quality services to over 10,000 clients.

Advanced Production Equipment

State-of-the-Art Welding Machines

Wheelchair suppliers production involves a process known as welding that plays a crucial role in maintaining the structural strength of the frame itself. INTCO Medical relies on cutting-edge welding equipment to create seamless joints for their wheelchairs. By utilizing this technology to its full potential they are able to minimize imperfections and bolster the overall durability of the wheelchair frame ensuring users can rely on its long lasting quality.

Mature Injection Molding Workshops

The use of mature injection molding workshops allows INTCO Medical to produce high-precision plastic components that are essential for both manual and power wheelchairs. This process ensures consistent quality across all parts, reducing the risk of malfunctions or wear over time.

Comprehensive Product Assembly Lines

Having a structured assembly line is essential to uphold the quality of products consistently in the market space.INCO Medicals detailed assembly lines encompass production phases starting from putting together components to final checks and verifications. Every step is closely observed to guarantee that each wheelchair meets the stringent quality standards before being released for sale.

Intelligent Warehousing Systems

Effective warehouse systems play a role, in handling inventory and guaranteeing timely product deliveries at INTCO Medical. The company utilizes warehouse systems that enhance storage and distribution procedures all while upholding ideal conditions to preserve product integrity. These systems greatly aid the company in fulfilling customer needs without sacrificing quality standards.

Rigorous Product Testing Procedures

Slope Testing for Stability

Stability is one of the most critical factors in wheelchair suppliers performance, especially when navigating inclines or declines. To address this, INTCO Medical conducts slope testing at angles ranging from 8-9 degrees, simulating real-world conditions where motor power may be insufficient or uphill braking might fail. This test ensures that all wheelchairs can handle such challenges safely and effectively.

Noise Testing for Quiet Operation

Users who use power wheelchairs often find that noise levels can greatly affect their comfort and overall experience with the device they rely on daily for mobility support. To ensure a user experience and minimize disruptions caused by operational sounds INTCO Medical conducts rigorous noise tests to ensure that the noise emitted during wheelchair usage stays below 65dB. This thorough testing procedure showcases the company’s commitment, to improving user satisfaction by focusing on even the smallest details.

Fatigue Testing for Durability

Ensuring the longevity of a wheelchair is crucial to its reliability and safety during use over long periods of time. INTCO Medical rigorously tests its wheelchair models through fatigue testing which involves more than 6000 continuous load cycles to confirm that no parts detach or break under such conditions.

Drop Testing for Impact Resistance

INTCO Medical includes drop testing, in its quality assurance processes to make sure that wheelchairs can withstand drops or impacts while being transported or used daily. The test assesses the strength of each wheelchair under stress conditions to ensure they remain dependable even in unexpected situations.

Brake Testing for Safety Assurance

Safety measures such as brakes play a role in preventing mishaps and instilling trust in wheelchair users while they are in operation. The assessment of brakes through testing determines how well they work and their dependability in situations; this adds an extra level of safety, for users.

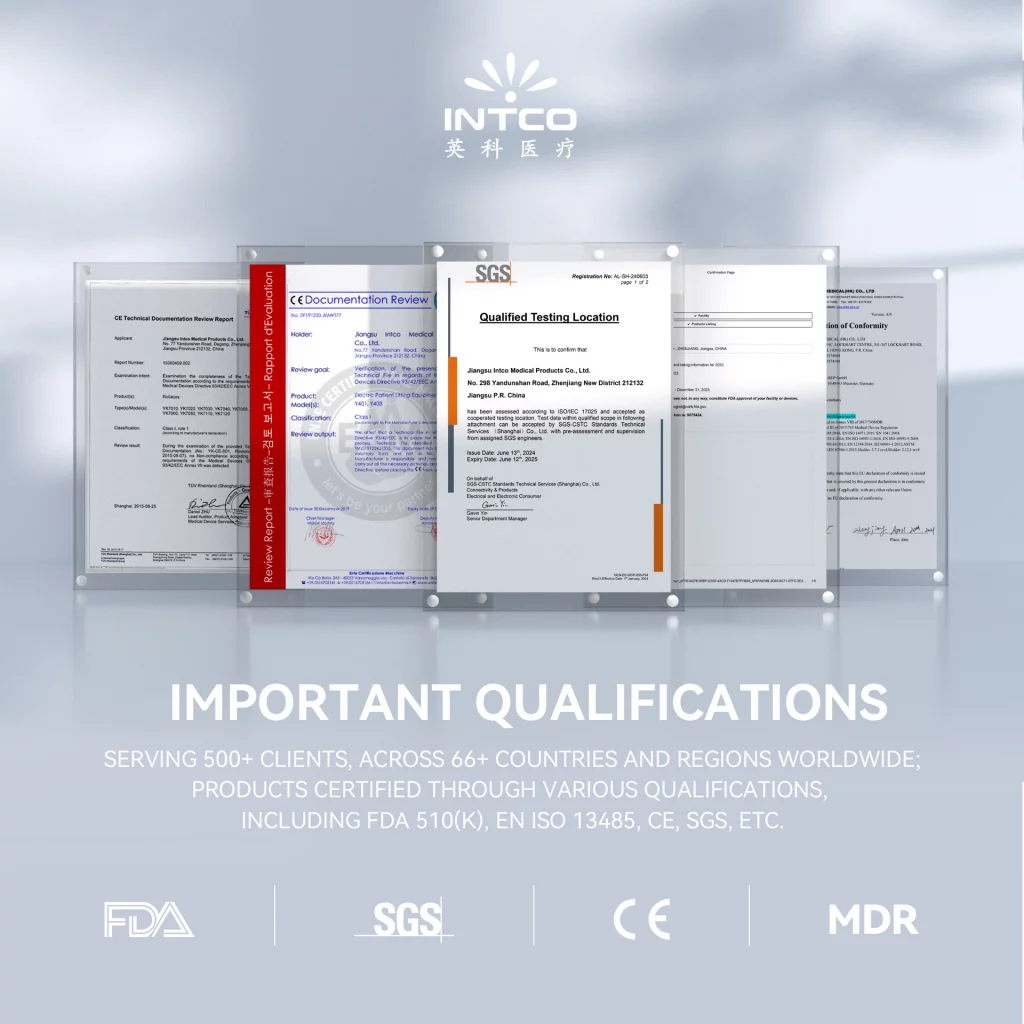

Compliance with International Certifications

FDA Certification Standards

To sell wheelchairs in the U.S. wheelchair suppliers need to meet safety standards like FDA approval to guarantee the products are safe and reliable for users by adhering to performance and labeling regulations, for improved safety measures and effectiveness of mobility aids offered to consumers.

ISO Quality Management Systems

Implementating ISO quality management systems is crucial, for maintaining high product standards in the wheelchair industry. Wheelchair suppliers adopt ISO systems to enhance their manufacturing processes and ensure efficient production. These systems emphasize improvement by helping wheelchair suppliers detect and address any issues promptly. Specifically focusing on wheelchairs ensures that each product meets stringent quality standards consistently.

CE Marking for European Markets

Wheelchair suppliers aiming for markets must acquire CE marking, a vital requirement indicating compliance with European health and safety standards and environmental regulations for their products, like power wheelchairs This certification assures customers that the wheelchair has undergone rigorous assessment and testing before being introduced to the market.

SGS Verification and Testing Services

To ensure the quality of products is up to par with standards in the industry and trustworthy for users’ needs and safety concerns alike, various wheelchair suppliers work alongside organizations such as SGS. These independent bodies offer testing and validation services that cover an array of criteria including performance metrics, durability levels, and safety standards crucial, for wheelchair users’ peace of mind.

Comprehensive Transport and After-Sales Services

Efficient Logistics and Delivery Solutions

It is crucial for operations to deliver wheelchairs to customers promptly without sacrificing quality during transportation to have efficient logistics, in place. Wheelchair suppliers utilize logistic systems to efficiently manage inventory and organize timely deliveries. Set up a production center for wheelchairs. These systems are created to manage quantities while ensuring proper storage conditions safeguarding the quality of each item until it reaches the final recipient.

Customer Support and Maintenance Services

Customer satisfaction and trust are significantly improved by after-sales services in the wheelchair industry where wheelchair suppliers provide support such as troubleshooting help and maintenance advice in addition, to offering replacement parts when needed for wheelchairs to operate smoothly over time without any unexpected problems or service interruptions.

Exploring INTCO Medical Products

Jiangsu INTCO Medical Products Co., Ltd, a branch of INTCO Medical, focuses on the research, production, and marketing of rehabilitation equipment and therapy products. We specialize in manual and electric wheelchairs, mobility scooters, transfer machines, walking aids, commode chairs, and canes. With hundreds of automated machines, we can produce 1,000,000 manual wheelchairs and 100,000 electric wheelchairs annually, serving over 66 countries and regions worldwide.

INTCO Medical guarantees our high-quality products that meet global requirements effectively. By following standards such as FDA approval and ISO certification and ensuring efficient supply chain management and strong customer service support in addition to offering a wide range of products and maintaining a focus on innovative design approaches.