Contact Us

Key Qualifications and Certifications for Chinese Wheelchair Manufacturers

Importance of Qualifications and Certifications for Wheelchair Manufacturers

The wheelchair manufacturer you choose must hold the qualifications and certifications to ensure that the products they deliver are both reliable and of high quality. Having these credentials not only helps to build credibility for wheelchair manufacturers but also increases their market value and reputation by complying with the rules and regulations of the industry. Apart from enhancing the credibility and the financial performance of wheelchair manufacturers, these credentials take a manufacturer to higher ground by complying with industry requirements and benchmarks.

Ensuring Production Technology Standards

Since the wheelchair has end users who will solely rely on them, the wheelchair company has to apply technologies and technologies in the design of their products that ensure that the wheelchair sustains rigorous safety and durability standards. Wheelchair manufacturers must use technologies and techniques during the product design process so that the wheelchairs adhere to safety and durability standards and requirements that people who rely on them must meet.

Testing and Laboratory Capabilities

Wheelchair manufacturers need to create testing facilities to test their wheelchairs, so that the quality and functionality of the product can be verified, including the durability and safety of wheelchairs. This means wheelchair manufacturers putting up testing facilities to ascertain the quality and activities of wheelchairs, torment testing the toughness and security parts of wheelchairs too.

Design Capability Accreditation

Accreditation in design capability is vital for manufacturers who wish to innovate and create user-friendly wheelchair designs. This involves having a team of skilled designers who can develop ergonomic and aesthetically pleasing products that cater to the diverse needs of users.

Comprehensive Sales Competence

To market wheelchairs internationally, manufacturers need to understand the sales dynamics, including whether to target markets based on consumer choice and regulations. Wheelchair manufacturers can increase their consumers with the help of implementing sales strategies and strengthen their foothold in the market. Through the formulation of sales strategies, manufacturers of wheelchairs can target an even larger consumer base and avail their stronghold on the market.

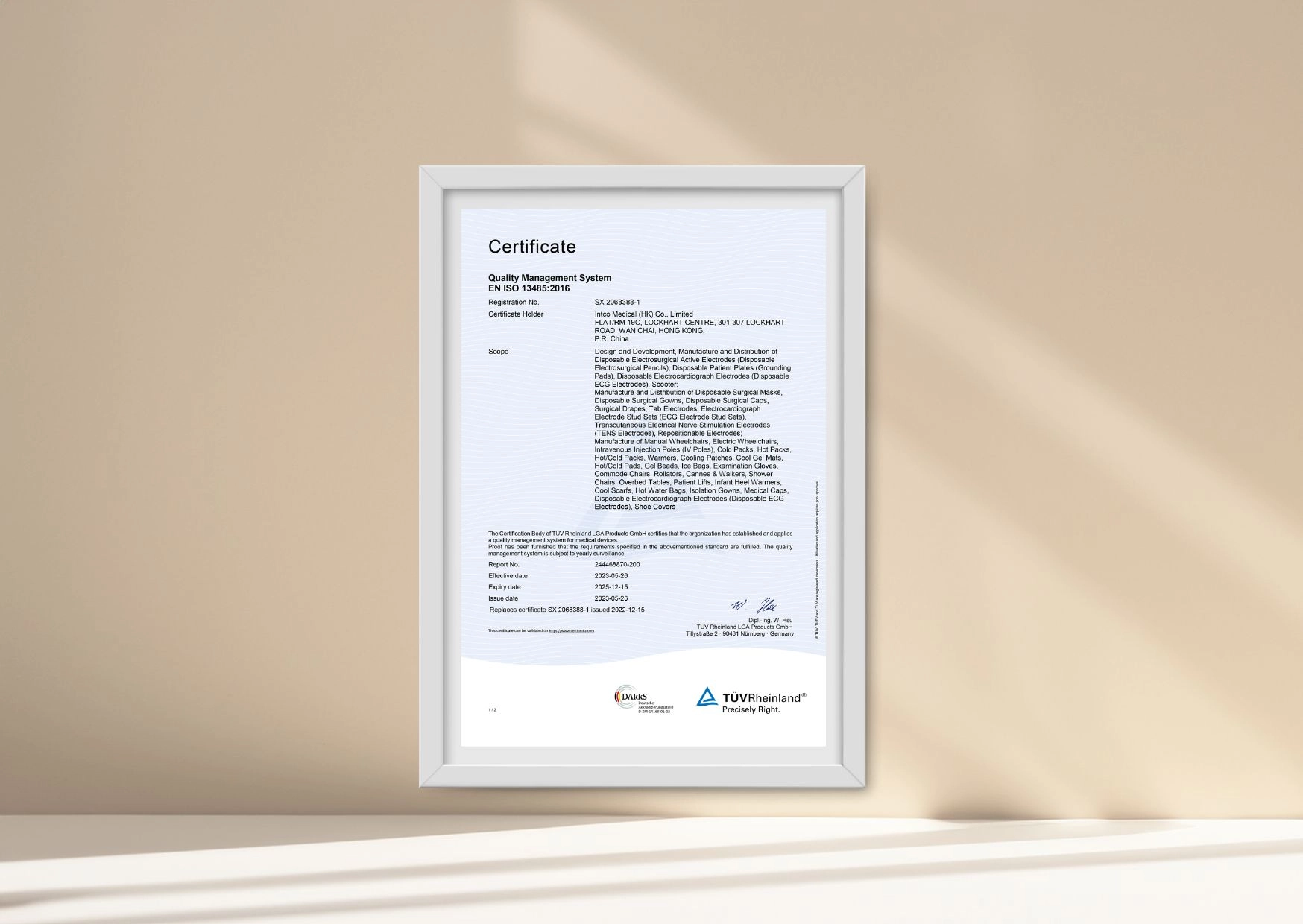

ISO 13485 Quality Management System General Requirements

Wheelchair manufacturers must obtain ISO 13485 certification to demonstrate their commitment to implementing high-quality management systems.

Establishing a Traceability System

Ensuring that all components used in production meet quality standards, and enabling recalls when necessary, is crucial for effective monitoring systems.

Ensuring Unified and Compliant Information

Manufacturers then need to make certain that every detail of their products is uniform and satisfies the specifications, such as tags, instruction manuals, and documents that specify the features of a product and usage instructions. Manufacturers need to keep their products uniform and in line with each other and specifications; even include tags, instruction manuals, and documents that directly specify the attributes and use of the products.

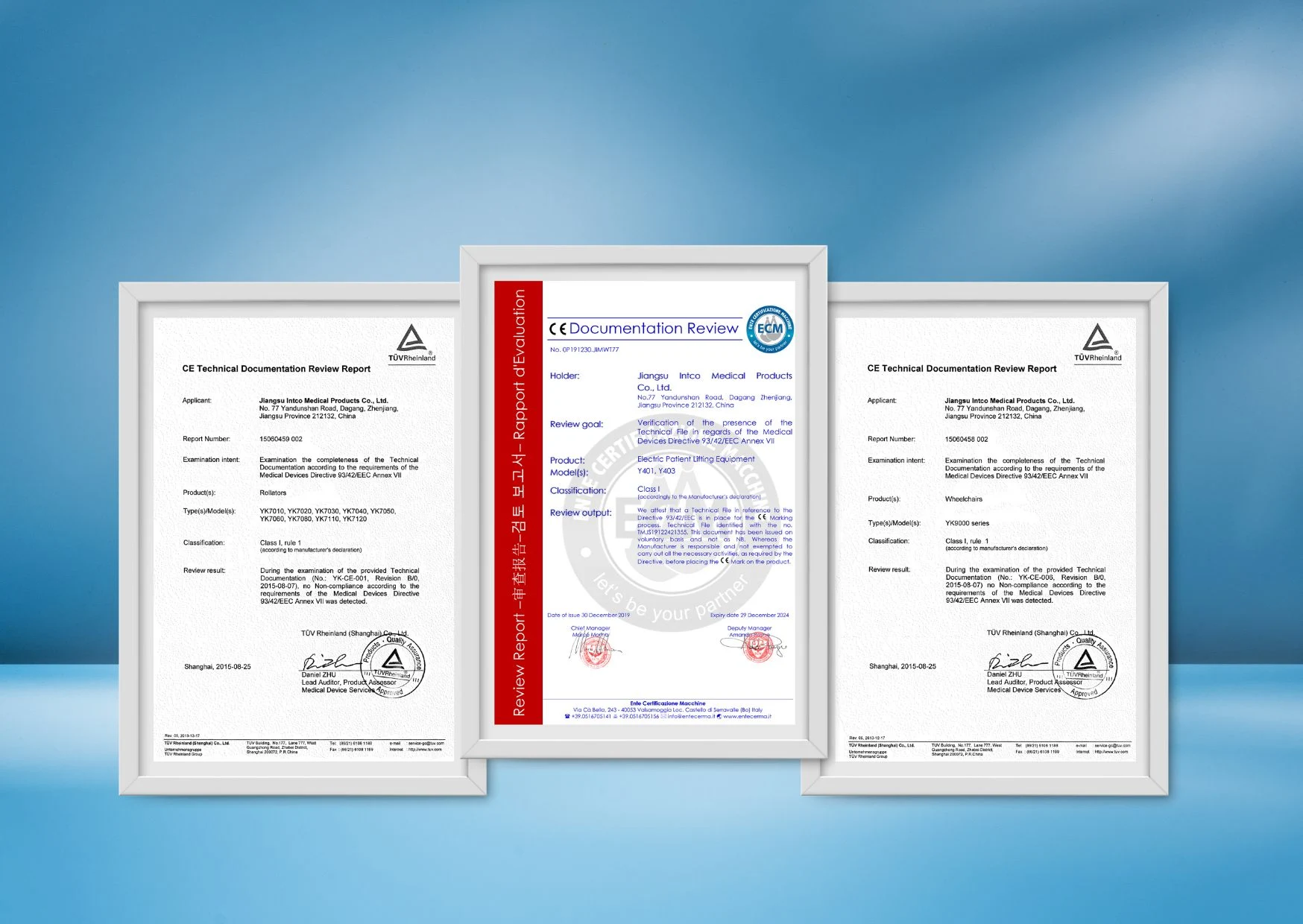

CE Certification for the European Market

To sell wheelchairs in the European Economic Area (EEA), wheelchair manufacturers must obtain CE certification demonstrating adherence to safety and standards specified in EU regulations.

Design Documentation Certification

Certification of design documentation for wheelchairs requires documenting the design process and demonstrating compliance with rigorous standards that focus on ensuring user safety. The design documentation that must be submitted for certification of wheelchairs includes records of the design process and evidence of compliance with stringent standards, giving priority to the safety of the user.

Risk Analysis Certification

Wheelchair manufacturers need to pass through the certification process, in which it is required to complete risk analysis to find the risks associated with their products and establish methods to adequately reduce these risks. When you take a stand in this process, you can avoid accidents or problems that you may encounter in the use of the wheelchair product.

Test Report Certification

Presenting the results of the test to validate that a product fulfills the requirements of a product standard (e.g., demonstrating the operation of a wheelchair and its performance in various circumstances, thus enhancing standardization reliability). Certification of test reports means doing tests to confirm that the product fulfills the test standards, demonstrating how the wheelchair functions or performs under a variety of different situations, and enhancing its dependability.

These credentials and certifications help industry professionals prove their commitment to making quality and safety-centered mobility aids that meet user needs and also serve devices that enhance user quality of life in wheelchair design and manufacture. Thus, seeing such credentials and certifications in the wheelchair manufacturing and design industry, professionals in the field can prove their commitment to quality and safety in mobility aids in order to address the needs and well-being of users.

FDA Certification for the U.S. Market

For wheelchair manufacturers wishing to enter the U.S. market, receiving the green light from the FDA is a critical milestone, in that it confirms that the company’s products meet the FDA’s performance standards for safety and effectiveness, market, since it ensures that their merchandise meets the safety and efficacy standards set by the Food and Drug Administration.

Durability Test Data Requirements

To gain FDA approval for their products, wheelchair makers need to provide evidence of test results demonstrating durability: that the wheelchair can be used safely and effectively over an extended period of time to cover wear and tear; that weight capacity and durability standards are met since the wheelchair must be able to withstand at least 5 years of use; etc. To gain FDA approvals for their creations, wheelchair manufacturers have to provide test results demonstrating that the wheelchairs can safely and effectively withstand daily use over long-term durations, as well as demonstrate that the standard weight-load safety and durability requirements are met to properly survive through wear-and-tear.

QSR 820 Production System Compliance

In accordance with a critical standard for getting a green light from the FDA in the healthcare field – the Quality System Regulation (QSR) – it describes methods of manufacture and quality assurance practices that ensure manufacturers of wheelchairs produce the best quality wheelchairs. Adhering to the Quality System Regulation (QSR) is significant for FDA approval in healthcare since it lists down how the manufacturer should manufacture their products and in what way the quality of those products should be ensured, guaranteeing an overall output of quality wheelchairs from wheelchair manufacturers.

INTCO: Leading Chinese Wheelchair Manufacturer

As one of the famous brands in the production and manufacture of medical wheelchairs and mobility scooters, INTCO Medical is a high-tech manufacturing company committing to R&D, production and marketing of medical consumables and durable medical equipment with main business covering medical consumables, rehabilitation equipment, physiotherapy care, etc.

Up to now, with a good product reputation, INTCO Medical has been exported products to more than 120 countries and regions in America, Europe, Asia, Africa and Oceania, which is providing practical products and high-quality services to over 10,000 clients.

Jiangsu INTCO Medical Products Co., Ltd, a branch of INTCO Medical, focuses on the research, production, and marketing of rehabilitation equipment and therapy products. We specialize in manual and electric wheelchairs, mobility scooters, transfer machines, walking aids, commode chairs, and canes. With hundreds of automated machines, we can produce 1,000,000 manual wheelchairs and 100,000 electric wheelchairs annually, serving over 66 countries and regions worldwide.